2025-2030 UNIFIED FACTORY STOCK RULES

SECTION A PROTEST RULES / CLAIM RULES/ FEES

1. Built engine protest fee will be $500 For top end and $500 for bottom end, protesting driver must finish in top 3 and on lead lap. Top end inspection includes heads, intake, bore, stroke, and full carburetor inspection. There will be no top end inspection for 602 crate engine, full engine must be protested. The protest fee for 602 crate engines will be 1200.00.

2. The Crate engine claim fee will be the current cost from a reputable dealer. The claiming driver must finish in the top 3 and on the lead lap. Engine removal will be overseen by tech officials and turned over to the claiming team as it comes from GM. Whatever distributor is in the engine will go with the engine.

3. Shock claim rule will be $125.00 per shock. The claiming party must finish in the top 3 and on lead lap.

4. If the team whose engine or shocks are being claimed damages the part being claimed either accidentally or intentionally, the result will be automatic disqualification. They will retain ownership of damaged equipment and the claiming team will be refunded their money.

5. Tire protest fee will be $200. Any driver in the field may protest the tires of any driver in the field after qualifying, heat races, or feature.

6. A total car protest will be $1800 and includes complete engine, transmission, rear end, and all suspension components.

7. Any protest or claim must be turned into tech officials within 10 minutes of completion of protesting party’s feature race.

8. If either protesting party backs out of protest after paying protest fee, $100 will be retained by track.

9. Any driver that refuses any claim or protest will be automatically disqualified

10. In the event of a protest and back protest, the winner’s car will be inspected first. If the winner’s car/engine is found to be illegal, the back protest will be null and void. The disqualified driver will be given his/her back-protest fee back (minus 100.00) and the second-place car will be inspected as it would have had before the protest.

SECTION B SAFETY RULES

1. Racing helmet (not motorcycle or DOT) SA 2010 or newer

2. Full racing fire suit required.

3. Fire rated racing gloves required.

4. 5-point racing harness mounted per manufacturers specifications required.

5. Two-pound fire extinguisher mounted within driver’s reach is required. (gauge must be good)

6. Racing seat properly mounted per manufacturer’s specifications required. (Full containment seat strongly recommend)

7. Properly mounted racing fuel cell required.

8. If the fuel line runs inside the car, it must either be in metal tubing (conduit) or be braided line.

9. All weights and the driveshaft must be painted white.

10. A 10-pound fire extinguisher is required at the trailer of each car competing in competition.

11. Racing (fire rated) shoes required.

12. Window net not required but recommended. When utilizing a window net, net must be removable from the interior and exterior of the car.

13. If the battery is in the driver compartment, it must be mounted properly and inside a battery box.

14. All cars are required to have a .125 thick steel intrusion plate on drivers side door bars (16”x26” minimum)

SECTION C WEIGHT RULES

1. Total weight required is 3300 lbs.

2. A one (1) pound per lap weight break will be given for the feature race only.

3. Any lead or ballast must be painted white and have the car number on it.

4. There is no longer a weight break for a Hans device or full containment seat, but both are highly recommended.

5. No weight or ballast may be placed on rearend or suspension components.

6. No weight will be allowed to be mounted above the firewall decking anywhere on the car.

SECTION D BODY RULES

1. All body panels must be fabricated from steel or aluminum, fiberglass roof allowed if it is a stock replacement roof for year, make, and model. No late model roofs. No fiberglass/composite doors, fenders, quarter panels, or hoods.

2. Body must be stock appearing for the make, model, and year of car.

3. The only allowed decking will be behind driver’s seat from door to door, (1) 8” section max on passenger side from rear of car to dash, (1) 6” section max on drivers side from rear of car to dash, and dash decking may not extend any farther than the steering wheel. No boxing in of driver compartment allowed.

4. Must have stock steel firewall in stock location from frame rail to frame rail.

5. Must have factory steel or fabricated steel floor pan and must run from front firewall to rear of driver’s seat. If floor plan is fabricated, it must be same thickness steel or thicker as factory and retain factory shape.

6. An aluminum or steel firewall is required from frame rail to frame rail behind the driver seat. The rear firewall must extend from frame rail to decking.

7. Rear of car may be open.

8. Aftermarket plastic front and rear covers permitted but must be stock appearing. (No Dominator Camaro style nose pieces). Filler panel between hood and plastic nosepiece may only be as wide as nose and be a maximum of 6” long.

9. Absolutely no spoilers

10. No spoiler sides

11. Driver compartment may not be boxed in.

12. No flat side bodies, doors, and quarters must taper inward at bottom towards the center of car.

13. No flat roofs, the roof must have a roll front to rear to resemble a stock roof.

14. No sharp bends in hood or fenders. Both must gradually roll towards nosepiece.

15. No raised lips or sharp edges on the body.

16. May have hole in hood for air cleaner clearance only, no other holes allowed. No hood scoops allowed.

17. Plastic skirts allowed at bottoms of doors and quarter panels, but no plastic wheel skirts/flares allowed.

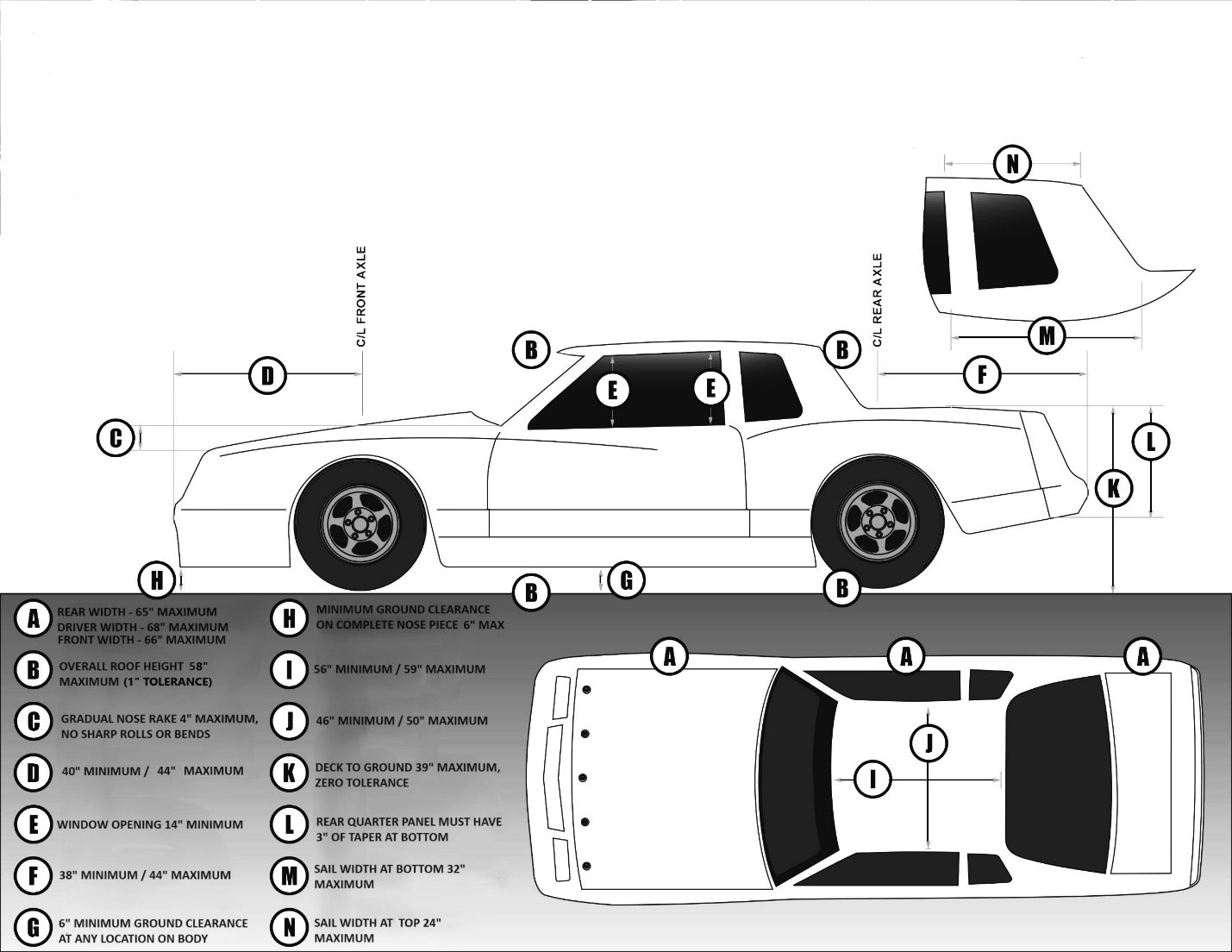

18. Please see body diagram for body measurements and rules.

SECTION E BRAKES

1. Dual master cylinders with hanging pedals are permitted.

2. No brake adjuster inside cockpit, may be mounted under hood on firewall.

3. No cut-offs of any kind on any corner of the car.

4. Must have four wheel working brakes. (If car is jacked up, and wheels spun, all 4 corners must stop)

5. Must be stock type, single piston, steel/cast iron calipers.

6. Steel rotors only, no exotic metals.

7. No gun drilled or scalloped rotors.

8. Disc or drum brakes ok.

SECTION F STEERING

1. All steering components must be stock for year, make, and model unless otherwise noted.

2. May run aftermarket steering box but must be cast iron and in stock location.

3. No heim end components.

4. Center link must be stock size for year, make, and model of car.

5. Stock type head or block mounted power steering pump only.

6. Steering quickener is allowed.

7. Collapsible steering shaft allowed.

8. Heim joint steering shaft guide allowed.

SECTION G FRONT SUSPENSION

1. All factory mounts on frame must be in stock location.

2. Upper A frames may be tubular aftermarket, but must have a cross shaft and be a maximum of 1” difference LF and RF. (No adjustable length A frames)

3. Upper A frames must be in stoke holes on tower, no slotting of factory holes.

4. Spindles must match the year, make, and model of car being raced. (No 3-piece spindles)

5. Lower control arms must match year, make, and model of car being raced, no modifications to length of A frame. (Ball joint placement must be stock)

6. Aftermarket steel or rubber bushings are allowed in lower A frames.

7. Adjustable cups allowed. (No screw jacks/jack bolts or raised buckets)

8. No bump stops or bump springs, no internal bump stops.

9. No chains, cables, or droop limiting devices of any kind.

10. No notching of frame for steering arm clearance.

11. No shimming of shocks, shocks must mount flat against factory location at bottom and in stock location at top. (Stock retainer clips allowed)

12. Spring rubbers allowed.

13. Racing springs allowed.

14. Screw in ball joints allowed, no adjustable height ball joints allowed. Ball joint must be in stock location on lower A frame.

15. Any length ball joint is ok.

16. Five-inch diameter springs required.

SECTION H REAR SUSPENSION

1. No spring raised buckets; upper spring perch must be in factory location.

2. Adjustable cups allowed.

3. Racing springs allowed.

4. Spring rubbers allowed.

5. No bump stops, bump springs, internal bump stops

6. Lower springs perches must be centered on top of axle tube.

7. Upper shock mount must be in stock location and shock must be mounted flat against mount. No shimming shocks down.

8. Lower end of shock must be mounted at same height, angle, and location on rearend. The lower mount must be behind and below the bottom of axle tube. (1/2” tolerance)

9. Aftermarket tubular (round, square, or rectangular) trailing arms allowed but must be non-adjustable and stock length.

10. Trailing arms must have stock type rubber bushings, no monoballs or heims.

11. Lower trailing arms must be 2 ¾” +/- ½” from bottom of axle tube and must be the same measurement (no offsetting)

12. Lower trailing arm mount at frame must be the stock mount and in stock location.

13. Upper trailing arms to be 3” +/- ½” from center of mounting bolt to top of rearend, must be same on both sides.

14. Center of axle tube to center of mounting bolt to be 7 ¾” +/- ½”, must be the same on both sides.

15. Upper trailing arm mount must be in stock location and trailing arm must be mounted in factory holes on chassis.

16. Trailing arm mounts on rearend may not be adjustable by means of twisting the mount on rearend, mount must be in a fixed welded position.

17. No bump stops/bump springs on rear suspension.

18. Lowering blocks are ok, must not be adjustable.

19. Adjustable shackles are ok on leaf spring cars

20. Leaf spring rear suspension “only” may run shock extensions or shock spacers on rear of car only. If running extensions/spacers, both sides must be the same. If running spacers, they must bolt through factory holes.

21. No sliders on leaf springs.

22. Front leaf spring mount must be factory stock and be bolted in factory holes.

23. Leaf spring cars may run stock style “stud” mounted shocks or rubber bushing type shocks.

24. No chains, cables, or droop limiting devices.

SECTION I REAREND

1. Standard 9” Ford, 9” Ford floater, or GM OEM rearend allowed.

2. No aluminum hubs, rotors, calipers, center sections, tubes, housings, yokes, or spools allowed.

3. No cambered rearends/axle tubes allowed.

4. No limited slip, no lockers, no torque sensing differentials.

5. All spools must be magnetic steel.

6. No lightened or polished ring/pinion gears.

7. Aluminum axle caps allowed.

8. No gun drilled/lightweight axles.

9. GM rearend must run C-clip eliminators

10. Mini spool or full spool allowed

11. No lightened scalloped carriers

SECTION J SHOCKS

1. Shocks must be magnetic steel.

2. No Schrader valve or piercing valves.

3. Shocks must be non-adjustable.

4. No heim end shocks, must be stock mount shocks.

5. Must be smooth body, no threaded body shocks allowed.

6. No shock extensions, except on the rear of leaf spring cars.

7. No bump stops, bump springs, or internal bump stops on any corner. Shocks must fully compress.

SECTION K CHASSIS/FRAME/ROLL CAGE

1. 101” minimum wheelbase but must match factory wheelbase of car being claimed.

2. Camaro must retain unibody.

3. X bracing ok.

4. Must have (4) bars minimum in front of drive’s window.

5. No offset cages, down tubes must sit on or be in line with frame rails.

6. Camaros are the only chassis that will be allowed to be underslung under rear end.

7. Seat must be properly mounted to roll cage.

8. A minimum of three door bars on the driver’s side and two door bars on passenger side required.

9. Must have chains front/rear for wrecker.

10. Six-point cage required.

11. All cage tubing is to have minimum diameter of 1 ½” and .090 of wall thickness.

12. Frame to remain stock from center of rearend to steering component mounts on front.

13. From center of rearend to rear of frame may be replaced with round, square, or rectangular tubing.(2” x 3” or 2” x 4” recommended)

14. Stock section of frames may be boxed in for strength

15. Driveshaft loop is mandatory

SECTION L ENGINE/ENGINE COMBINATIONS

*602 crate engines allowed. Rebuilt 602 crate engines must meet all CrateRacin USA specs.

1. ENGINE LOCATION

A. Center or chassis. #1 spark plug must be in front or in line with upper ball joint.

2. ROTATING ASSEMBLY

A. Rods to be Eagle, Scat, or equivalent OEM style rods with press fit or floated pins. (Eagle #5700BPLW / Scat 31CR5700)

B. Pistons to be 4 eyebrow flat top or dished pistons. Pistons may be cast or forged. 3 ring grooves only. Stock diameter wrist pins. Piston material must extend past wrist pin boss. No gas porting. No cutting, drilling, or grinding on any part of the piston. Pistons must be stock replacement type pistons with stock configuration.

C. Crankshaft to be stock stroke Scat, Eagle, or equivalent OEM style cast or forged. Balancing allowed. No knife edge, no grinding. May balance on bottom of counterweights. 48 pounds minimum weighed with gear.

D. Deck height to be 0.00.

E. Bore to be 0.060 with 0.010 tolerance for wear.

F. 2 eyebrow flat top pistons allowed with 72CC EQ heads.

3. CAMSHAFT/LIFTERS

A. Camshaft to be .425/.425 maximum lift. (no tolerance)

B. Camshaft can be degreed.

C. No 4/7 swap cams

D. Stock diameter, stock replacement, flat tappet, anti-pump-up lifters only. No solid Lift lifters.

E. Lifters must have wire ring clip or snap ring/E-clip.

F. 0.00 Lash must be preloaded.

G. Double, triple, or true roller timing chain. No gear drives.

4. CYLINDER HEADS

A. OEM stock cast iron open chamber heads, Engine Quest EQ-CH350I, RHS #12400. Steel heads only.

B. 70 CC minimum combustion chamber on OEM heads and 72 CC minimum combustion chamber on EQ heads.

C. All heads to have 178 CC maximum intake runners.

D. 3 angle valve job allowed, but no final cut greater than 75 degrees.

E. Must use stock valve size for cylinder head. Maximum valve size to be 1.94 intake and 1.50 exhaust. No 2.02 heads. No vortec heads. No closed chamber heads. No angle milling, no porting, no polishing, and no gasket matching. No angle plug heads.

F. Bronze guides allowed. Stainless steel OEM stock replacement valves. Neck down and swirl polish allowed, .010 maximum step down.

G. 1.270 maximum O.D. valve spring diameter. No beehive, no wedge, no taper, and no dual valve springs.

H. OEM stock style spring retainers/keepers only. No lightweight, aluminum, titanium, or exotic materials. Rocker arms to be stock style, stamped steel with 1.5 ratio only. No roller tip or roller body.

I. Screw in studs, guide plates, poly locks, and 7/16 studs allowed. No stud girdles.

J. Stock length and diameter push rods only, hardened allowed.

5. INTAKE

A. OEM GM, Quadrajet, or Holley stock style cast iron intake only. No bowtie or marine intakes allowed.

B. Edelbrock 2701 is the only aluminum intake allowed, must have part number.

C. No porting, polishing, or gasket matching.

6. CARBURETOR

A. The only carburetor allowed will be the Holley 4412 500 CFM two-barrel carburetor. Must have choke horn. Any metering block/plate allowed. Metering block and base plate may be billet, nothing else may be billet. Carburetor may be steel or aluminum with any finish or color. Must pass all go/no go gauges. Must have conventional boosters. Must have stock style Holley discharge nozzles.

B. No XP carburetors

C. 1” maximum carb spacer or adapter, may not run both. The total allowed thickness with 2 gaskets will be 1.350.

D. This carburetor must pass the complete set of BLP performance gauges (Guage kit # 7860)

SECTION M TRANSMISSION/CLUTCH/DRIVESHAFT

1. Factory stock automatic or manual transmission (No racing transmissions)

2. All transmissions must retain all working gears in operational condition, all forward and reverse must work.

3. No Racing Transmissions

4. No Power Glide Transmissions

5. No dummy torque converters for automatic transmission, 10” converter minimum

6. No direct drive transmission or direct drive couplers

7. Steel flywheel only

8. Stock type clutch and pressure plate only, 10” minimum. No triple disc clutches.

9. Clutch must be full circle; no puck style clutches.

10. Steel driveshaft only, must be painted white.

11. Clutch, pressure plate, and flywheel must have a combined weight of 30LBS minimum weighed

without bolts.

SECTION N EXHAUST

1. Cast iron stock type manifolds allowed

2. Headers allowed, but must be inside frame rail headers only

3. Mufflers allowed

4. Outlet may not exceed 3” diameter

5. No stainless headers, no tri-y headers, no square tube headers

6. All pipes must be parallel to the ground

SECTION O TIRES/WHEELS

1. Hoosier H500 only

2. No grooving, No siping, No needling, No drilling

3. 8” steel wheels maximum

4. Bead locks allowed on any corner

5. Any offset allowed

6. Wheel spacers allowed on any corner

7. ABSOLUTELY NO TIRE PREP/CONDITIONER!!!

SECTION P IGNITION

1. Any stock type one wire HEI Ignition

2. No MSD boxes allowed

3. No soft touch rev control

4. No circuit board modules, but aftermarket performance module allowed

5. No traction control allowed

6. Battery must be securely mounted in a battery tray/box, 12 volts only

7. May use billet distributor housing

8. Distributor may be locked by any means or may use curve kit with springs

9. Alternator allowed

SECTION Q FUEL

Fuel, Fuel Cell, and Fuel Pump Rules:

1. Racing type fuel cell mandatory, 32 gallon maximum, must be securely mounted in the trunk area of the car, inside a .20 gauge metal box supported by a minimum of 2” x 1/8” steel straps. Fuel Cell must have roll over check valve in fuel cell vent.

2. Fuel cell must be completely visible from rear of car.

3. Gasoline, Racing Gas, or E-85 fuel allowed. No methanol or alcohol, no oxygenated fuel. None of the following chemicals are allowed in any fuel used for competition: No nitrous oxide, propylene oxide, nitroethane, MTBE, hydrazine, or ethylhexanol.

a. Gasoline or Race Gas – specific gravity NOT to exceed .744 at 60 degrees. Any gasoline or race gas with a specific gravity of .745 or greater will be disqualified. Fuel is subject to testing on site, or fuel samples may be taken and sent to an independent lab for testing.

b. E-85 – specific gravity not to exceed .7855 at 60 degrees. Any E-85 with a specific gravity of .7856 or greater will be disqualified. Fuel is subject to testing on site, or fuel samples may be taken and sent to an independent lab for testing.

c. It is the competitor’s responsibility to know what is being put into their fuel cell.

d. VPMR9, MR12 or THEIR EQUIVALENT NOT PERMITTED

STOCK BLOCK MOUNTED FUEL PUMP IN STOCK LOCATION ONLY!!